-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

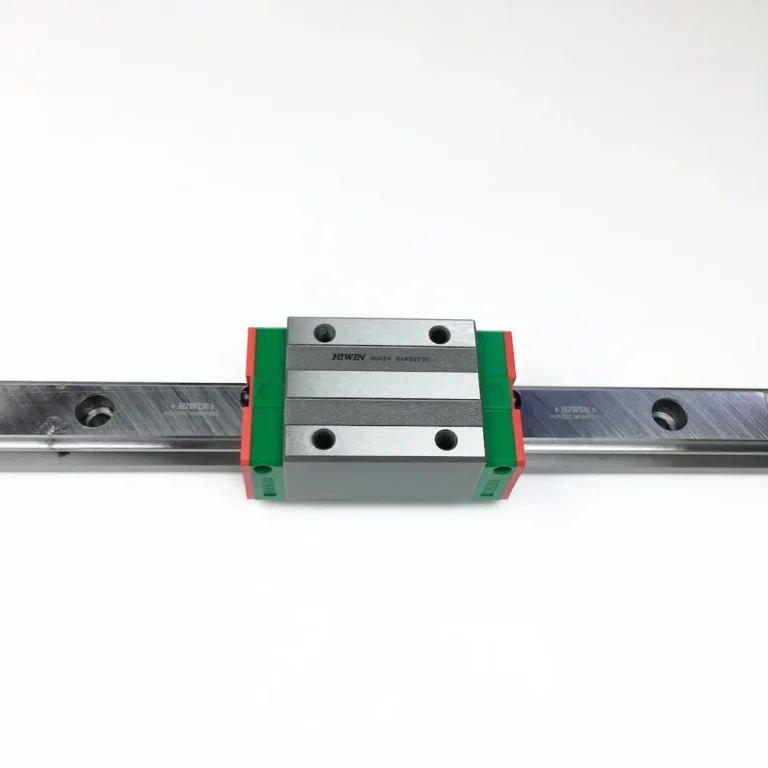

What is the preload in linear bearing block?

Many users will see the parameter of preload before purchasing a linear bearing block, so what is this parameter? What does it affect? How to understand and select the preload correctly?

First of all, let’s get technical:

What is the definition of preload?

Preload refers to a certain amount of load force on the roller in advance, can also be said to increase the diameter of the steel ball, through the use of negative gap between the ball and the bead channel to give the preload, in this way, so that the rolling body and the guideway, the contact surface of the slide to produce elastic deformation, the formation of a preloaded state, and to eliminate the gap, but also to reduce vibration and noise. By increasing the appropriate preload, the rigidity of the entire linear bearing block can be increased. Generally speaking, each manufacturer’s linear block model is different, series is different, and preload is different, but generally speaking, they can be divided into the following categories.

Choosing the correct preload will make your production twice as effective and help the working life of the LM block, but too much preload will reduce the working life, so please choose the correct preload value for yourself carefully.

If you’re still confused about linear bearing block preload,

Let me give you two examples from daily life to help you understand better.

In fact, preload can be generally understood as “the degree of tightness between linear rails and linear bearing block”.

1. Screw tightness:

Imagine you are screwing screws, if fully tightened (large preload), there is no gap between the screw and the nut, more stable, but the rotation of the effort; if a small gap (small preload), although the rotation of the flexible, but easy to wobble. Guideway preload is by adjusting the slider and guideway “tightness”, so that the linear drive system is both stable and flexible.

2. Take the bus

when the car is full of people (preload), there is no gap between the various passengers, the car bumps when people are difficult to shake (high rigidity); when the car is less people (preload is small), the passengers are easy to sway left and right (have a gap). The preload of the guide rail is like the state of the number of passengers in the bus. Ball diameter setting is also the same reason: if the ball diameter (similar to fat passengers), the rail and the slider will be stuck tighter (preload), sliding resistance, but more stable; replaced by a slightly smaller ball (thin passengers), sliding more smoothly, but there may be a gap.

Therefore, the role of preload is mainly to eliminate gaps, improve rigidity (as hard as pressing two boards harder to break after bending, preload after the guide can withstand greater loads without deformation). Reduce vibration: A tightly fitted linear rail in high-speed motion is less likely to produce shaking or noise, similar to car tires with or without adequate tire pressure.

At this point, I think you have a clearer idea of preload. Next, let’s discuss the influence of preload.

Influence of preload

1. Positive effects – as mentioned above, eliminating clearance, increasing stiffness, reducing vibration, and so on.

2. Potential Problems – Friction and Temperature Rise: If too much preload is selected, the friction between the rolling element and the raceway will increase, leading to heat generation and grease failure in the linear bearing block. This will result in abnormal fatigue wear of the rollers in the linear bearing block. – Installation difficulty: The higher the preload, the higher the requirement for parallelism and rigidity of the mounting surface.

Therefore, it is strongly recommended not to select the preload blindly, or the consequences will be endless.

Conclusion

Pre-load as a linear guide performance optimization of the core parameters, is through the physical adjustment of the guide system to achieve “both stable and accurate” balance state, the need to achieve a balance between rigidity, precision and life, similar to adjusting the bicycle chain tension – too loose will fall off the chain, too tight will be laborious, too loose will fall off the chain, too tight will be laborious, too loose will fall off the chain, too tight will be laborious, too tight will be laborious. A chain, too tight is laborious to find the right “tightness” to ride smoothly.

Choosing the right amount of preload can significantly improve the performance of your equipment. However, for complex conditions, it is still advisable to consult the manufacturer’s manual or a professional engineer.