-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

What is linear bearing?

If today’s world industry is compared to a giant, then the motor will undoubtedly play the role of the heart. In this giant’s body, linear bearings and linear guideways are definitely a blood vessels, the blood is like the product, and the blood vessels will supply blood to of the body various places, together forming a whole set of industrial systems. Undoubtedly, without linear motion systems, it would be difficult to transport the products to various parts of the production facilities, resulting in a significant reduction in production efficiency.

So what exactly are linear bearings? And how do they work in a production environment?

Let’s start by taking a look at the video below, which gives a good illustration of how linear motion bearings work:

As shown in the figure below, where the red arrow points to where the linear bearings are located, the sliding table is fixed to the linear bearings, and the CNC spindle in the figure is directly linked to the sliding table, it can be seen that the linear bearings take on the role of transmission and are responsible for transporting the various parts of the machine tool that need to be adjusted in position in real time.

The red arrow in the figure below points to the linear bearing guide, which is used to support the motion of the linear bearings, which move in a straight line on the linear guideway.

So let’s go through this video and address the question of WHAT LINEAR BARRIERS ARE and come to a more superficial conclusion at this point:

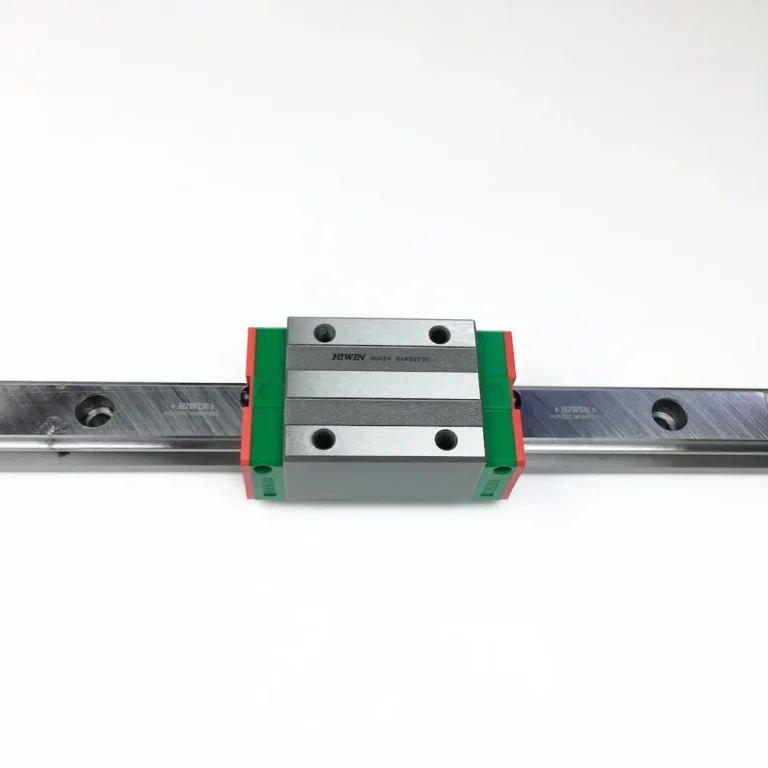

Linear bearings do linear motion in the linear guide, and the user can connect linear bearings to the slide, and then connect the slide to the CNC machine unit, in order to achieve the realization of the purpose of changing the position of the production equipment, such as the video of the linear bearings, it is very good to realize the CNC spindle displacement on the machine, but because the linear bearings can only make linear motion, so the realization of the Z-axis processing of the CNC spindle. The picture shows a full view of the linear bearings:

Why we call it a linear bearing and how it relates to rolling bearings?

As shown in the figure, you can clearly see the rows and rows of balls in the linear ball bearing, linear ball bearing through the internal ball and guideway contact surface to form a four-point or multi-point support structure (for example, Four-row ball design), the load is uniformly transferred to the guideway, so as to bear the weight of the workpiece or equipment, and at the same time, the balls in the slider cyclic rolling, through the rolling friction instead of sliding friction, reducing the direct pressure between the contact surfaces of the conventional transmission medium, and at the same time, the centralized load is distributed to a number of contact points to avoid excessive local stress. This is one of the reasons why we call it a linear bearing.

There is another reason, because linear bearings are extremely precise, in linear bearings, because linear bearings replace the traditional sliding friction by internal ball rolling friction between the linear guide and the linear bearing, which significantly reduces the transmission resistance in the machine tool and ensures Smooth motion and positioning repeatability (to the sub-micron level) can greatly improve machining efficiency and accuracy.

So, what is linear bearing?

It is a linear motion device loaded on an LM Guide to perform linear displacement, and can be connected to a load platform to perform linear motion along the LM Guide. It can reduce a lot of friction and achieve μm accuracy. The use of the LM Guide in conjunction with the LM Roller is a sure way to dramatically improve the accuracy and mechanical efficiency of equipment.