-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

What factors affect the accuracy of linear bearing ball carriages?

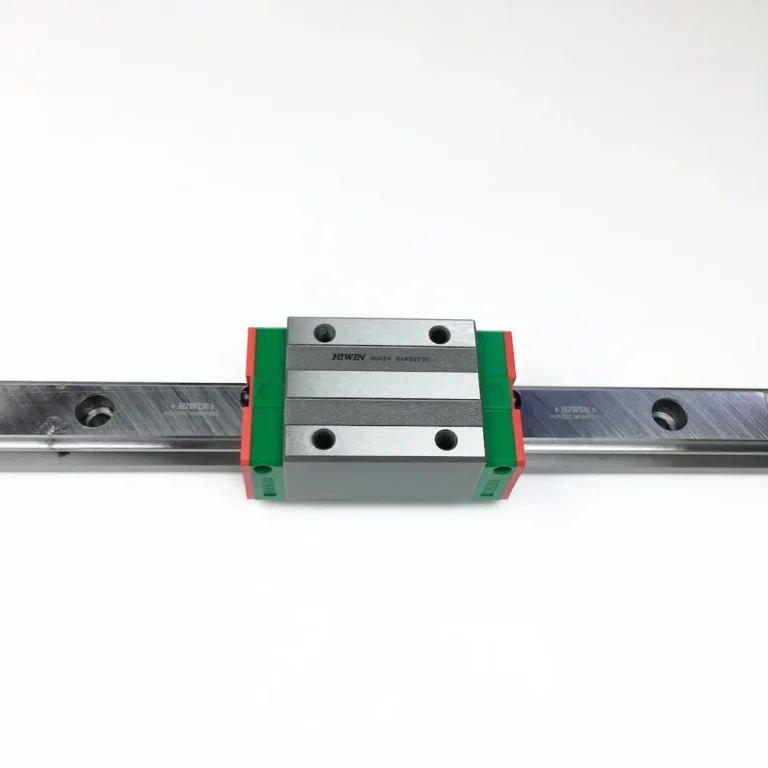

In today’s world, the industrial system is developing rapidly and is already on its way to Industry 4.0. One of the most significant benefits is in the field of industrial automation, where the linear motion system has become one of the most sought-after industrial modules due to its high transmission efficiency. In this, the linear bearing ball carriage and linear rail as the linear transmission, one of the key components, its precision directly affects the positioning accuracy of the equipment, the smoothness of movement and processing quality, efficiency, and other key features. So, what are the reasons that affect the accuracy of linear bearing ball carriages and linear rails?

1.Manufacturing Factors

Material selection: the wear resistance, coefficient of thermal expansion, and hardness of the linear bearing ball carriage material will directly affect its long-term stability. If the manufacturer chooses the material with too big difference in coefficient of thermal expansion, then it is very easy to lead to deformation and dimensional error when the linear bearing ball carriage movement heats up. But at present, the leader brands of products basically do not need to consider these issues, their original factory products can basically meet the precision in the working life, the error remains unchanged, while some miscellaneous sliders are prone to linear bearing ball carriage material selection of uneven problems, resulting in processing accuracy problems.

Manufacturing process: for linear rails, straightness, parallelism and surface smoothness is the basis of accuracy. For linear ball bearing carriages, the roundness of the balls and the consistency of the dimensions are the key to the smoothness of the slider’s movement. Defects in machining equipment and processes can lead to uneven clearance between linear rails and linear ball bearing carriages, which can lead to accuracy problems. If the linear ball carriage and linear rails are machined with large errors, this can lead to even more serious consequences, such as uneven friction or vibration and other fatal problems.

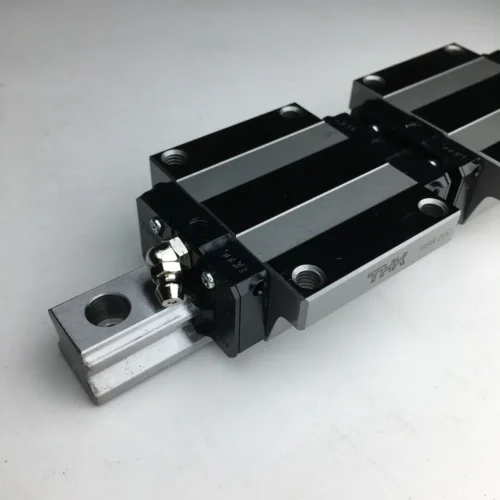

It can be seen that the quality of linear bearing ball carriage and linear rails is extremely critical, which will directly lead to the subsequent accuracy problems, so we recommend choosing the leader brands, where quality and assembly process are guaranteed, such as INA, THK, and other major brands.

2.Installation and Load Factors

Flatness of the Mounting Platform: If the flatness of the mounting platform is not up to standard, it will cause the entire linear motion system to shift. It is like the difference between a new straight and level road and a rough and broken mountain road. Similarly, for the linear rails and linear ball bearing carriage , the flatness of the LM rail is very sensitive due to the slide table . The slightest unevenness combined with the load can cause the linear rails to deflect and deform, resulting in damage to the linear ball bearing carriage and the entire linear motion system.

Load on the entire linear motion system: The entire linear motion system supports the table in reciprocating motion, so the load on the slide table becomes critical. If the load on the slide table exceeds the rated load or if there is severe eccentric loading, it is very likely that the linear ball bearing carriage will fail, ultimately causing irreparable damage to the entire system.

3. Operating Conditions and External Environment

Speed and acceleration: high-speed operation, if the load is very large, then the huge inertia force may trigger linear rails and linear ball bearing carriage instantaneous detachment or vibration, then need to reduce the load, or reduce the start-stop speed.

Temperature Variations:

Temperature changes alter the linear guideway dimensions via thermal expansion. Operating outside the recommended temperature range may lead to:

In high-temperature environments:

The thermal expansion of the metal linear guideway degrades geometric accuracy and stability. Increased clearance between the linear guideway and linear bearing carriage, compromising fit precision.

In low-temperature environments:

Sharply increased lubricant viscosity (grease may harden or solidify), raising sliding resistance/torque.

For a 300mm linear guideway, a temperature difference (ΔT) >2°C between its ends induces a thermal expansion error:

Humidity: High humidity accelerates rust formation on the linear bearing carriage and linear guideway. Vapor-phase corrosion inhibitors (VCI) are recommended for protection.

Contaminants and Vibration: Dust, metal chips, or other pollutants entering the linear bearing carriage can accelerate wear or cause roller seizure. External vibration (e.g., equipment resonance) may loosen the linear guideway or induce fatigue cracks.

4. Maintenance and Wear Management

Cleaning and Dust Protection : By using seals or dust covers, the ingress of contaminants can be minimized. For example, the linear guideway and linear bearing carriage used in semiconductor equipment must operate in a dust-free environment to maintain micron-level accuracy.

Lubrication Condition: Insufficient lubrication will significantly increase the coefficient of friction, accelerate wear, and even cause stick-slip motion (intermittent sliding at low speeds). Regular use of specialized grease or oil can maintain smooth motion. High-speed, light-load applications require low-viscosity lubricants to minimize drag. Heavy-load applications require high-viscosity grease to increase film strength.

Specific lubricants must still be selected in accordance with the manufacturer’s guidelines or regulatory requirements.

Wear Monitoring and Replacement: After prolonged use, uneven wear may occur on the linear guideway surface, leading to deviations in the linear bearing carriage’s travel path. Periodic inspections and timely replacement are critical.

Conclusion

The accuracy of the linear ball bearing carriage is the result of the comprehensive effect of the entire process of design, manufacturing, installation, use and maintenance. To ensure its performance, it is necessary to start from product selection, strict installation, environmental control and regular maintenance. Although it is a bit troublesome, its excellent transmission performance is still the best choice.

References

ISO 230-2:2014 Machine tool accuracy test standard