-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

How to Troubleshoot Linear Block Guide Sticking

The linear block guide is one of the important transmission parts in the processing equipment. The smoothness of its operation directly affects the performance and stability of the equipment. However, in actual use, the linear block guide may sometimes become stuck, which undoubtedly has a huge negative impact on the operation of the equipment and processing efficiency. This article introduces 3 troubleshooting points for linear block guide stuck to provide readers with practical solutions.

1. Cleaning and lubrication

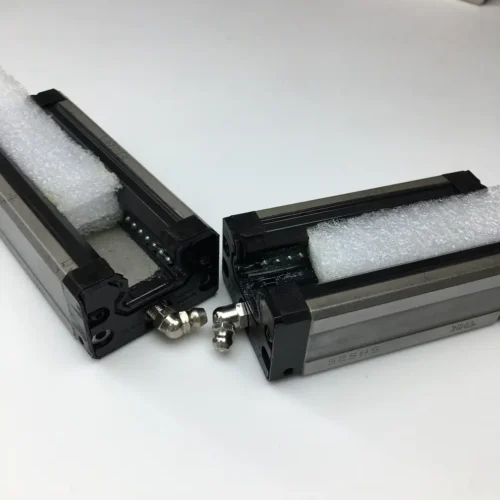

The linear guide carriage usually experiences sticking because the linear motion guides or linear guide carriage are contaminated or the lubricant is insufficient. During processing, waste materials such as metal swarf and coolant/lubricant may be left on the linear motion guides, which will cause the linear guide carriage to move difficultly, and even wear the linear guide carriage, reducing its service life. Therefore, regular cleaning of the linear motion guides and linear guide carriages is the main way to prevent sticking and extend their service life.

One of the key factors for the smooth operation of the linear guide carriage is lubrication. Proper lubrication can reduce the friction between the linear guide carriage and the linear motion guides, making the wear smaller and the service life longer. After cleaning the linear motion guides and linear guide carriages, remember to apply lubricant to ensure smooth movement of the linear guide carriage.

If the linear guide carriage is always sticking. You can ask the technician to check whether there are metal swarf and coolant/lubricant splashed on the linear motion guides, causing the linear guide carriage to stick and be difficult to move. If this is the case, clean the linear motion guides and take proper lubrication measures to significantly improve the sticking of the linear guide carriage.

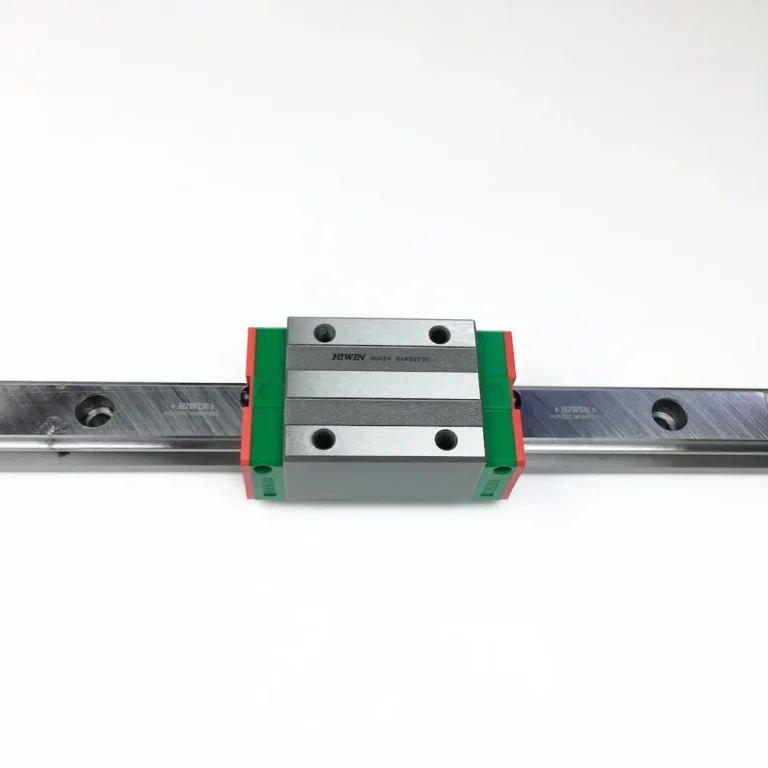

2. Check the matching accuracy of the linear guide carriage and the linear motion guides

The linear guide carriage needs to match the linear motion guides well to make the linear guide carriage slide more smoothly. In some cases, the linear guide carriage is stuck because there is a problem with the clearance fit between the linear guide carriage and the linear motion guides. If the clearance fit is large, the linear guide carriage and the linear motion guides will vibrate when working, resulting in inaccurate positioning; if the clearance fit is small, it will cause increased friction, and the linear guide carriage and the linear motion guides will wear each other or even get stuck.

In most cases, when troubleshooting the linear guide carriage, be sure to check the clearance fit between the linear guide carriage and the linear motion guides. If the clearance fit is found to be substandard, adjust the linear motion guides or linear guide carriage immediately to avoid significant economic losses.

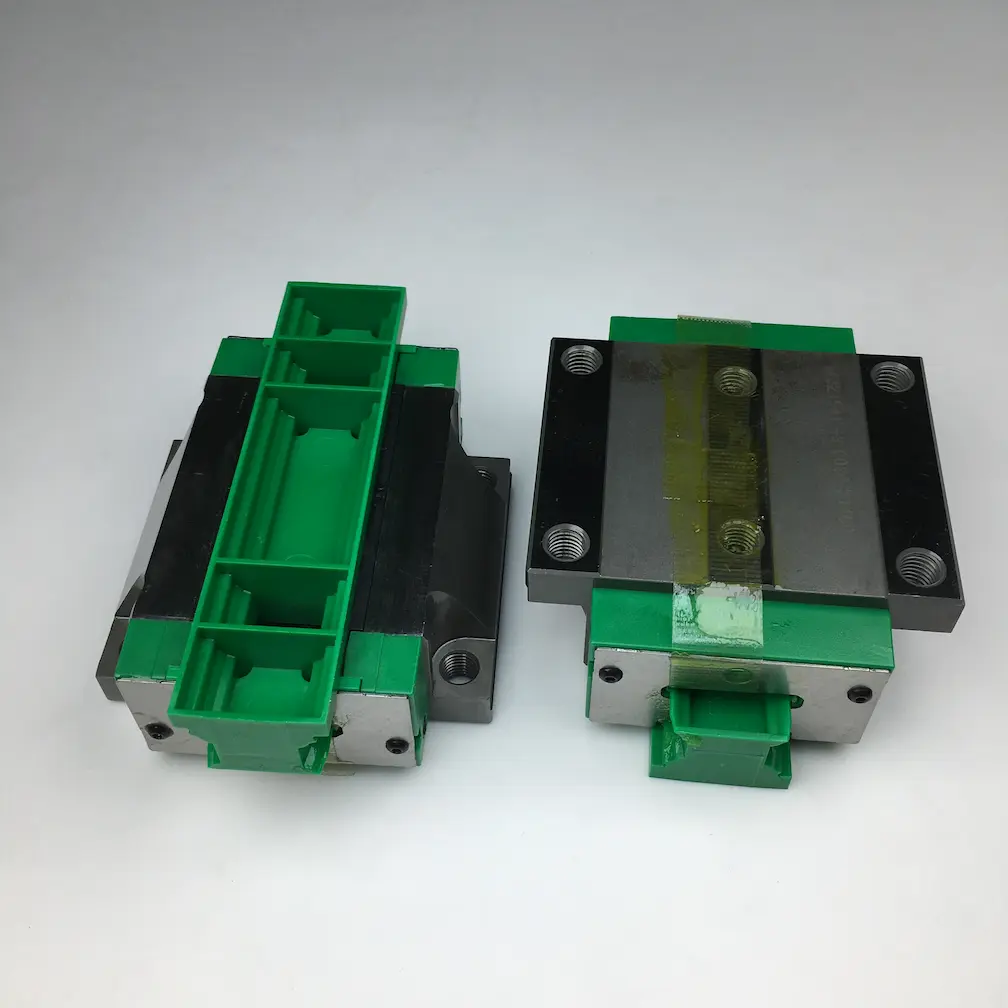

3. Check the electrical control system

For machining centers or machine tools with high automation, there are usually a large number of electrical control devices, which are also the key to whether the linear guide carriage is stable. From sensors to drives to control systems, they may all become fault points.

Cause analysis:

- Position sensors: such as linear encoders, magnetic linear encoders, and rotary encoders, are damaged or contaminated. These sensors are key components in closed-loop control systems, used to monitor the carriage’s position in real-time. Suppose the sensor itself is damaged (for example, the reading head fails, the scale is damaged, the internal electronic components fail), or is contaminated by oil, chips, dust, etc.. In that case, it will cause inaccurate, lost, or unstable position signals, causing the control system to misjudge, causing the carriage to stick, exhibit inconsistent movement, or inaccurate positioning.

- Sensor signal cable problems: Cable degradation, damage, poor electrical contact (for example, loose plugs, oxidation), shielding layer damage causing electromagnetic interference, etc., will affect the stable transmission of signals and cause abnormal operation of the linear guide carriage.

Conclusion

To troubleshoot the problem of linear guide carriage sticking, in addition to the above points, there are actually many small problems to be troubleshooted in the actual process. The best way to understand these small problems is to have a comprehensive understanding and knowledge of linear guide carriage and linear motion guides. You can read other articles on this website to learn more systematically about linear guide carriage and linear motion guides from basic to advanced knowledge.