-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

How to calculate the lifespan of a linear bearing block?

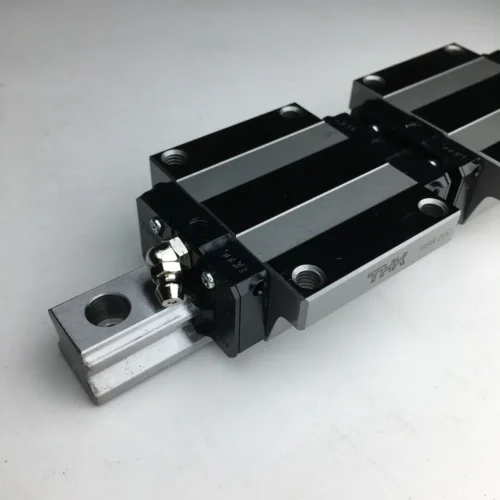

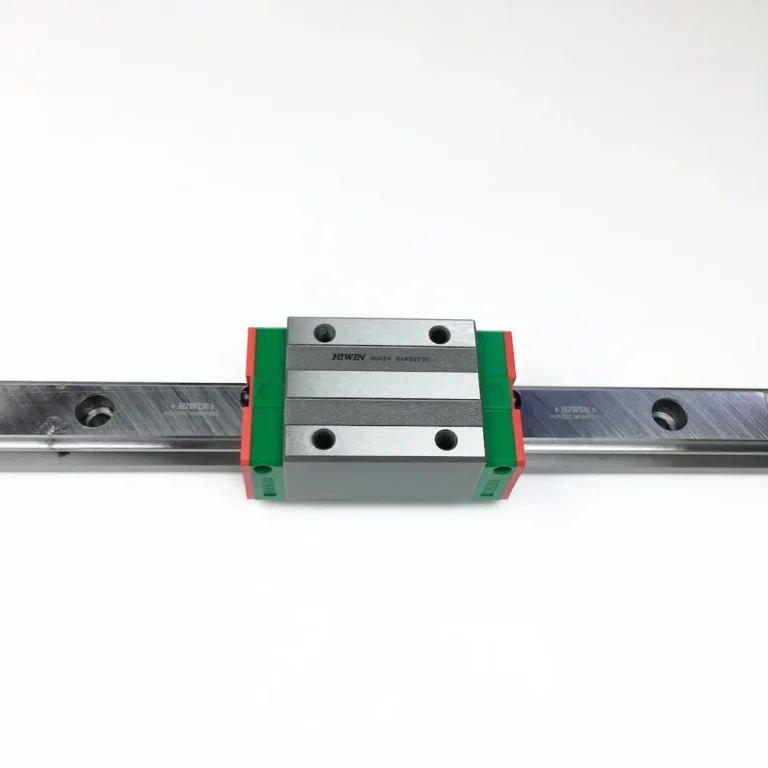

The linear bearing block is a critical component of linear transmission, playing a vital role in daily processing operations. In a similar vein, the linear bearing block, a component of precision engineering, is subject to degradation upon initiation of its production or utilization. The assessment of its service life becomes paramount. According to the findings of the study, proactive stocking can be implemented to avert unanticipated downtime and mitigate financial losses.

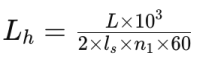

The following formula is used to calculate the expected lifespan of a linear ball bearing block:

The following formula is used to calculate the expected lifespan of a linear roller bearing block:

In both formulas:

L : nominal life

C : basic dynamic load rating

P : applied load

fh : Hardness factor

ft : Temperature factor

fc : Contact factor

fw : Load factor

This formula is employed to calculate the expected lifespan of the linear bearing block under anticipated operating conditions.

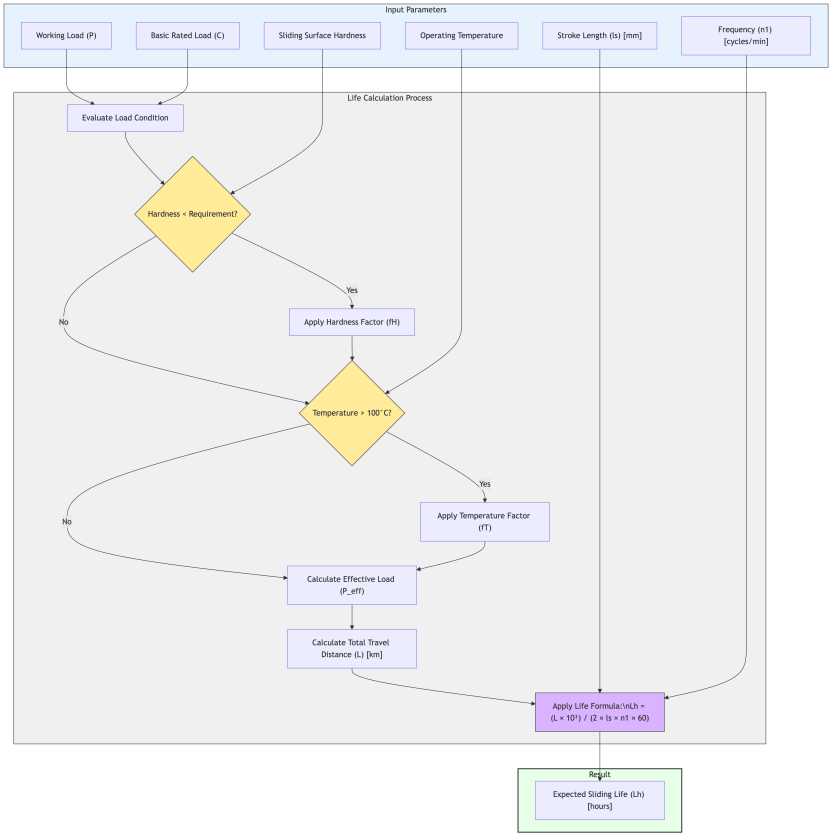

Relationship between HRC and lifespan

The PMI factory linear bearing block serves as a case study. According to the official description, the rolling surface of the linear bearing block exhibits a hardness of HRC greater than or equal to 58, with a definition of Fh set at 1.0. The accompanying figure depicts the official hardness coefficient chart, which delineates a hardness coefficient of HRC greater than or equal to 58 for the rolling surface of the linear bearing block.

It can be seen that when the HRC is 40, Fh is only about 0.3. Substituting into the formula, you can see that the service life is nearly two-thirds less.

Relationship between temperature and lifespan

The subsequent graph illustrates the official temperature coefficient, Ft, and temperature relationship, indicating that the PMI series linear bearing block functions optimally within a temperature range of 100°C or less. It has been demonstrated that the product life expectancy is reduced by 10% when it is exposed to a 150 °C environment.

Let’s use an example to calculate the lifespan of a linear bearing block

If we have the following work environment

The lifespan of linear bearing block is

If you want to calculate the service time of a linear bearing block, you can use the formula below:

We have a working environment below:

Reciprocation frequency means 10 times/min.

And then, the service life (time) of the linear bearing block is:

Please note that the unit of the result of this formula is hours. The result(1944h) is equivalent to running for a duration of 24 hours per day, which can be sustained for approximately 81 days consecutively. The subsequent chart is intended to facilitate a more profound comprehension of the formula.

The calculation of the life expectancy of a linear bearing block is of paramount importance. This calculation enables the prediction of the replacement cycle of the linear bearing block, thereby facilitating effective inventory management. The accuracy of these calculations is enhanced under normal maintenance conditions, with the formulas providing close to perfect results. These formulas are essentially standardized across brands and apply to all models of linear bearing blocks.