-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

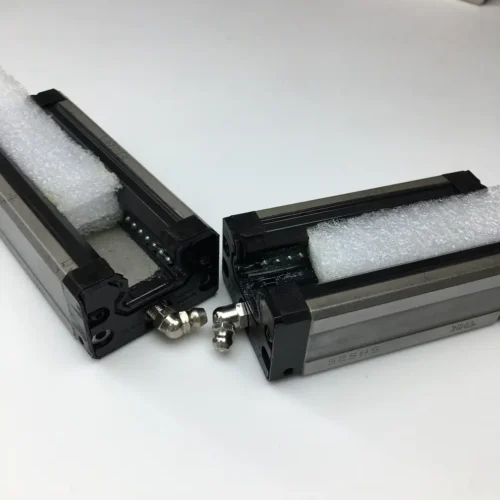

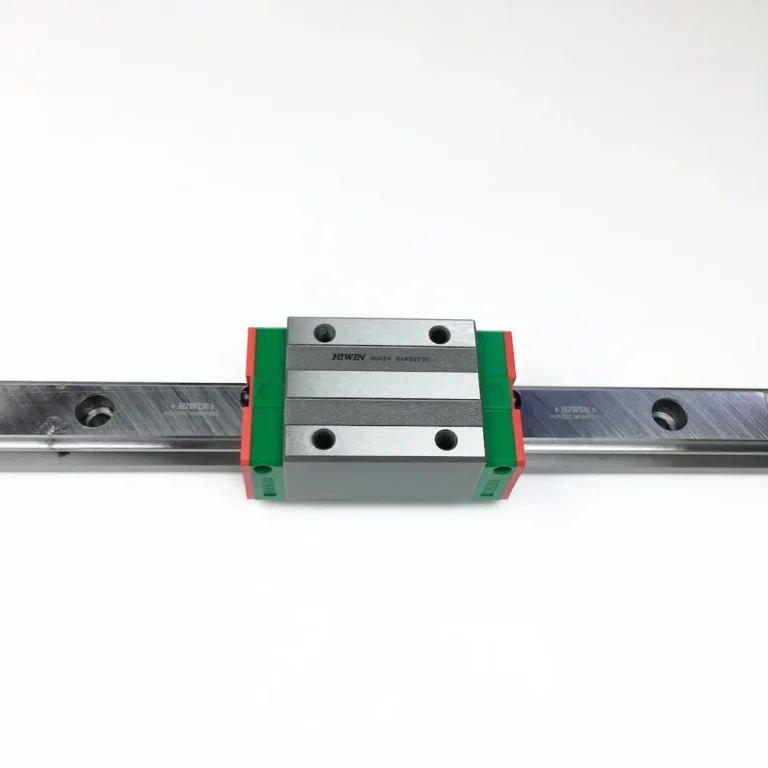

Features of linear bearing blocks

200 years ago, machining equipment relied on sliding contact with metal or cast iron to achieve linear motion.100 years ago, roller guides and ball bushings were introduced for linear motion. 50 years ago, the emergence of linear bearing blocks injected new vitality into major machining equipment and machine tools.

This evolution demonstrates that the development of linear bearing blocks has advanced in tandem with industrial progress. Conversely, industrial growth has also driven innovations in linear bearing blocks and similar transmission systems. As one of the most critical transmission components today, why are linear bearing blocks so indispensable to modern industrial development and production?

Extremely High Positioning Accuracy

When using the linear bearing block as a linear guide, since the friction mode of the linear motion guide is rolling friction, not only is the friction coefficient reduced to 1/50 of the sliding guide, but also the difference between dynamic friction and static friction becomes very small. Therefore, there is no slippage when the table is running, and there is no idle slippage even during micro-feeding, so that positioning accuracy in the μm range can be realized.

Low wear to maintain accuracy over time

The traditional plain bearing guide will inevitably cause the platform to move with poor accuracy due to the oil film backflow effect, and because of the movement of the lubrication is not sufficient, resulting in the wear of the contact surface of the linear motion rail, which seriously affects the accuracy. The rolling guide has very low wear, especially the lubrication structure is simple, easy lubrication, excellent lubrication effect, can make the friction contact surface of the lowest wear, so it can maintain the accuracy for a long time.

Can withstand loads in all directions at the same time

Due to the special bundle system structure design of the linear guide, it can simultaneously withstand the load in the up, down, left and right direction, unlike the sliding guide in the direction of parallel contact surfaces can withstand a lighter lateral load, which is easy to cause the machine to run with poor accuracy. The optimized design of the geometrical structure can simultaneously withstand radial, reverse radial, and lateral loads and maintain its running accuracy, and at the same time, its rigidity and load capacity can be easily improved by applying preload and increasing the number of sliders. Rigidity and load capacity can be increased by applying preload and increasing the number of linear bearing blocks.

Easy assembly and interchangeability

As long as the installation surface of the linear guideway is processed on a milling or grinding machine, and the linear guideway and linear bearing blocks are fixed to the machine with a specific torque, the high precision of machining can be reproduced, reducing downtime and production halts. Its interchangeable characteristics allow the linear bearing blocks to be arbitrarily attached to the same type of linear guideway , maintaining the same level of smoothness and precision. This simplifies machine assembly and maintenance.

Traditional sliding guideways require time-consuming scraping of the track. If the machine’s accuracy deteriorates, re-scraping is necessary. In contrast, linear guideways have interchangeability, allowing replacement of the linear bearing blocks, linear guideway, or even the entire linear guideway set, enabling the machine to regain a high-precision linear transmission system.

Conclusion

From metal sliding to precision rolling, the evolution of linear transmission history, the nature of the industrial processing system, the pursuit of precision, efficiency and reliability. linear bearing block its micron-level positioning ability to break the shackles of traditional friction, rolling body of the long-lasting low-loss reshaping of the mechanical life, load balancing design to meet the needs of all kinds of working conditions, modular interchangeability subvert the traditional maintenance mode. Modularized interchangeability subverts the traditional maintenance mode. In the future course of industrial development, the role of linear bearing block will be more irreplaceable!