-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

Calculation of Linear Rail Block Life Attenuation Under Harsh Working Conditions

In many cases, it can be said that the life of the linear rail block , calculated according to the official formula, is only for reference. Why? Because the linear rail blocks used in most machine tools often operate under relatively harsh and complex working conditions. In such situations, blindly referring to the rated life becomes meaningless. Having said that, harsh and complex working conditions are undoubtedly a heavy blow to the service life of the linear rail block .

These complex conditions include, but are not limited to, excessively high or low operating temperatures, excessive pollution or particulate contamination, localized corrosion caused by high humidity, inadequate lubrication, or incorrect grease selection. The above are just some common scenarios. Therefore, under these relatively harsh conditions, how to estimate the life of the linear rail block becomes very important.

Now, I will guide you step by step through the process of estimating its service life.

STEP1: Learn How the Rated Life of a Linear Rail Block Is Calculated

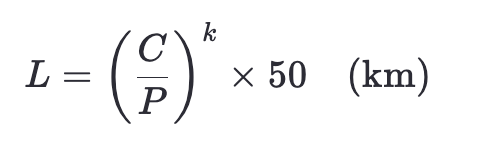

As we all know, the rated life formula of the linear rail block is…

Where:

- L: Rated travel distance life (km)

- C: Basic dynamic load rating (N or kN)

- P: Equivalent applied load (N or kN)

- k: Exponent factor — 3 for ball-type , 10/3 for roller-type

STEP2: Understanding Environmental Modification Variables in Linear Rail Block Life Calculation

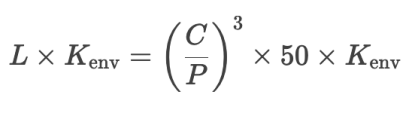

When encountering complex working conditions, the actual life of the linear rail block is often less than the rated life calculated by the above formula, which leads to incorrect judgment of the linear rail block’s service life by each production line and difficulty in stocking. Therefore, I introduce a variable Kenv , which is an environmental correction factor. The life of the linear motion guide will be reduced according to Kenv , which is usually less than 1.

So, the expected life formula of the linear rail block under complex working conditions becomes:

And Kenv is:

Kdust=reduction factor due to particulate contamination

Kcorr=reduction factor due to moisture and corrosion effects

Ktemp=reduction factor due to high operating temperature

Klub=reduction factor due to insufficient lubrication or extended lubrication intervals

SETP3: Understand how to Determine the Value of Each Environmental Correction Factor

Now the question is, how do you determine the value of the environmental correction factor? The following is my conclusion based on years of work experience, for reference only:

- Ambient Temperature Effects :

When the operating temperature exceeds 50°C, Ktemp≈0.9; when it exceeds 100°C, Ktemp≈0.7. It is worth noting that there is no fixed rule for Ktemp—this is only a reference value. The actual value will vary depending on brand, model, and environmental conditions. - Particulate Contamination :

In cases where light floating dust or particles are present on the ball or raceway of the linear rail block, Kdust≈0.9-1.0. When machining debris or heavy particulate contamination occurs, Kdust≈0.3−0.6. Since pollution levels are often subjective to assess, the values provided here are relatively conservative and should be adjusted based on real-world conditions. - Moisture and Corrosion :

When the linear rail guide operates in an overly humid environment (humidity > 80%) or is exposed to corrosive media, rust and corrosion may occur. In such situations, Kcorr≈0.5−0.8. However, if stainless steel material or anti-corrosion measures such as VCI are used, Kcorr≈0.9−1.0. - Lubrication Conditions :

If grease is insufficient or lubrication intervals are too long, metal-to-metal contact between the rolling elements and raceway increases wear significantly. In this case, Klub≈0.4−0.6. When the lubricant is sufficient and the lubrication cycle is short, Klub≈0.95−1.0.

Once again, please note that the above coefficients do not exist in isolation. In actual working conditions, it is necessary to multiply the environmental variables and then calculate them.

Special statement: The correction coefficients given in this article are based on experience rather than data, and rough calculations are better than detailed studies. In practical applications, it is recommended to take the lower limit of the conservative value, or to directly measure the life of key equipment. The tolerance of linear rail guides from different brands to working conditions varies greatly. For example, an original INA linear rail block you purchased from our website may be able to withstand Kdust=0.8 in a dusty environment, while low-end imitations may only perform at Kdust=0.3−0.4, which is optimistic.

In the final analysis, the life of the linear rail block is like Schrödinger’s cat — you will never know the actual amount of wear before opening the maintenance cover.