-

Address: Suzhou City, Jiangsu Province, China, 215000

-

Tel: 0086-512-68235075

Analysis of the Linear Guide Carriage series of HIWIN

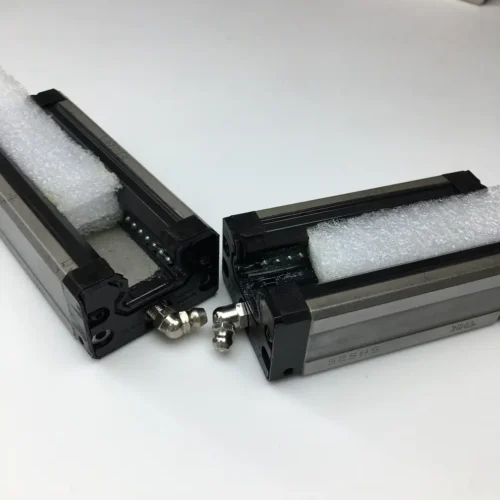

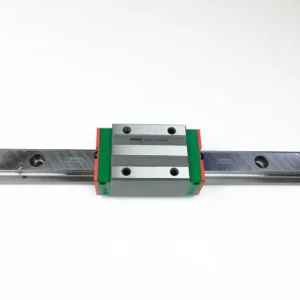

HIWIN Linear Guide Carriages

HIWIN is a major manufacturer in Taiwan, which is known for its extensive range of linear motion components. Its linear guide portfolio spans from heavy-duty machining to micro-precision applications. HIWIN emphasizes performance attributes such as load capacity, rigidity, and precision, and employs proprietary technologies like SynchMotion™ to achieve silent operation

HG Series (Heavy Load Ball-Type Rolling Element)

- Key Design Features :

- Ball-type rolling elements with an arc groove design, offering higher load capacity and rigidity compared to similar products.

- Four-direction equal load distribution (radial, reverse radial, lateral).

- Misalignment compensation functionality to absorb installation errors.

- Available in flange-type and square-type configurations.

- Size range: 15 mm to 65 mm.

- Accuracy grades: Normal (C) to Ultra Precision (UP) .

- Dynamic load rating: 11.38 kN to 208.36 kN

- Main Recommended Applications :

- High-speed, high-precision machinery requiring robust load-bearing capabilities.

- Widely used in machine tools (e.g., machining centers, CNC lathes), industrial automation, and general equipment demanding durable performance.

- Flange-type carriages are ideal for applications with gravity-induced moment loads due to their low profile and large mounting surface.

The HIWIN HG series enables high-speed, high-precision, and smooth linear motion with extended service life. This is achieved through its high load capacity, rigidity, four-direction equal load distribution, and misalignment compensation function. Flange-type carriages are particularly suited for gravity moment load scenarios, thanks to their low assembly height and wide mounting surface.

EG Series (Low-Profile Ball-Type Rolling Element)

- Key Design Features :

- High load capacity and rigidity within a compact footprint.

- Four-direction equal load distribution (radial, reverse radial, lateral).

- Misalignment compensation to absorb installation errors.

- Size range: 15 mm to 35 mm.

- Accuracy grades: Normal (C) to Ultra Precision (UP) .

- Dynamic load rating: 5.35 kN to 33.35 kN.

- Main Recommended Applications :

- Ideal for high-speed automation equipment and space-constrained environments.

- Maintains robust load capacity and rigidity despite its compact form, making it optimal for miniaturized machinery or limited mounting spaces.

- Low-profile design enables suitability for high-speed automation systems and spatially restricted applications.

- Features include low noise, high rigidity, and high load capacity with four-direction equal load distribution, combined with misalignment compensation for enhanced accuracy.

CG Series (High Torque Resistance Ball-Type Rolling Element)

- Key Design Features :

- Ball-type rolling elements with DB-type (O-type arrangement) bearing configuration.

- Up to 50% higher torque load capacity compared to HG Series due to optimized bearing arrangement.

- Integrated circulation unit ensures smooth motion.

- Optional guideway cover strips for improved contamination resistance.

- Four-direction equal load distribution .

- Size range: 15 mm to 45 mm.

- Accuracy grades: Normal (C) to Ultra Precision (UP) .

- Dynamic load rating: 13.8 kN to 124.43 kN.

- Main Recommended Applications :

- Designed for applications requiring superior torque load resistance, such as single-axis systems with offset/torsional loads.

- DB-type (O-type arrangement) provides longer moment arms than DF-type (X-type arrangement) for enhanced rolling moment capacity.

- Optimized lubrication system suits short-stroke operations.

- Common use cases include single-axis robots and gantry systems with cantilevered loads.

WE Series (Four-Row Wide Rail Ball-Type Rolling Element)

- Key Design Features :

- Ball-type rolling elements , wide rail design with four-row Gothic arch contact geometry.

- High load capacity, torsional rigidity, and moment rigidity.

- Equal rated loads in radial, reverse radial, and lateral directions (45° contact angle).

- Misalignment compensation functionality for installation error absorption.

- Low-profile structure with reduced center of gravity.

- Size range: 15 mm to 35 mm (varies by model: 17, 21, 27, 35, 50 mm).

- Accuracy grades: Normal (C) to Ultra Precision (UP) .

- Dynamic load rating: 5.23 kN to 29.8 kN (e.g., WEH50CA up to 61.52 kN).

- Main Recommended Applications :

- Ideal for space-constrained environments or high-moment-load scenarios requiring single-rail configurations.

- Common use cases: automation equipment, high-speed conveyance systems, precision measuring instruments, semiconductor manufacturing equipment, blow molding machines, and single-axis robots.

- Technical Advantages :

- The wide rail design enables high load/moments resistance while maintaining compactness.

- Application examples include automation systems and precision measuring equipment.

- Detailed specifications and applications are available in manufacturer documentation.

QH Series (Quiet Heavy-Duty Ball-Type with SynchMotion™ Technology)

- Key Design Features :

- Ball-type rolling elements with four-row Gothic arch contact geometry.

- SynchMotion™ (proprietary) technology for smooth motion, optimized lubrication, reduced noise, minimized dust generation, and extended service life.

- Interchangeable with HG Series (shared dimensions and accuracy grades).

- Size range: 15 mm to 45 mm (some models up to 65 mm).

- Accuracy grades: Normal (C) to Ultra Precision (UP) .

- Load capacity comparable to HG Series.

- Main Recommended Applications :

- High-precision manufacturing requiring high speed, low noise, and minimal particulate emissions.

- Examples: precision measuring equipment and semiconductor fabrication systems.

- Technical Advantages :

- Combines SynchMotion™ (proprietary) with wide rail design for enhanced performance.

- Detailed SynchMotion™ benefits and applications are documented in technical resources.

QE Series (Quiet Low-Profile Ball-Type with SynchMotion™ Technology)

- Key Design Features :

- Ball-type rolling elements with four-row Gothic arch contact geometry.

- SynchMotion™ (proprietary) technology for smooth motion, optimized lubrication, reduced noise, minimized dust generation, and extended service life.

- Low-profile design (reduced mounting height and shorter carriage length).

- Interchangeable with EG Series (shared dimensions and accuracy grades).

- Size range: 15 mm to 35 mm.

- Accuracy grades: Normal (C) to Ultra Precision (UP) .

- Load capacity comparable to EG Series.

- Main Recommended Applications :

- High-speed automation requiring low noise and compact installation.

- Common use cases: CNC machines (milling machines, lathes), robotics, medical equipment, and packaging machinery.

- Combines SynchMotion™ technology with EG interchangeability for smooth, quiet operation.

- Ideal for medical equipment and robotics due to its silent motion and precision.

QW Series (Quiet Wide Rail Ball-Type with SynchMotion™ Technology)

- Key Design Features :

- Ball-type rolling elements inheriting WE Series advantages (wide rail, high moment rigidity, single-track suitability).

- SynchMotion™ (proprietary) integration for quieter motion, enhanced lubrication, and longer lifespan.

- Interchangeable with WE Series.

- Ultra-low profile design with wide rail for torsional rigidity.

- Size range: 17, 21, 27, 35 mm.

- Accuracy grades: Normal (C) to Ultra Precision (UP) .

- Load capacity matches WE Series.

- Main Recommended Applications :

- Single-track systems or space-limited applications needing high moment rigidity and noise reduction.

- Common use cases: automation equipment, high-speed conveyance systems, and precision measuring instruments.

- Combines WE Series’ torsional rigidity with SynchMotion™’s silent operation.

- Emphasizes low noise, single-track compatibility, and torsional rigidity.

R Series (Quiet Roller-Type with SynchMotion™ Technology)

- Key Design Features :

- Roller-type rolling elements with four-row Gothic arch contact geometry (45° contact angle).

- Ultra-high rigidity and load capacity due to line contact surface.

- SynchMotion™ (proprietary) technology for low friction, smooth motion, reduced noise, and extended service life.

- Interchangeable with RG Series (shared dimensions and accuracy grades).

- Size range: 20, 25, 30, 35, 45 mm (some models up to 65 mm).

- Accuracy grades: High (H) to Ultra Precision (UP) .

- Load capacity matches RG Series.

- Main Recommended Applications :

- High-precision manufacturing requiring noise reduction and rigidity.

- Machine tools and systems combining roller-type advantages (high load capacity, high rigidity) with SynchMotion™’s smooth motion and low noise.

- Typical use cases: CNC machining centers, injection molding machines, and heavy-duty automation equipment.

- Technical Advantages :

- Combines ultra-high rigidity with SynchMotion™’s optimized lubrication and silent operation.

- Model codes and features are detailed in manufacturer documentation.

HIWIN Positioning Linear Guide System

- Key Design Features :

- Integration of linear guides from HG/QH/CG series with non-contact magnetic encoders .

- Combines high rigidity of linear guides and high accuracy of encoders.

- Embedded magnetic strip in the rail prevents damage and ensures durability.

- Optimized for precision applications requiring real-time position feedback.

- Main Recommended Applications :

- Automation equipment needing precise position control (e.g., semiconductor manufacturing, medical devices).

- Applications requiring simultaneous high rigidity and high-accuracy measurement.

H-type read head is ideal for space-constrained installations.

- Technical Advantages :

- The system merges linear guide rigidity with magnetic encoder precision, suitable for high-precision automation.

HIWIN’s product strategy demonstrates significant diversification , offering tailored series for nearly all foreseeable application requirements: heavy-load (HG, RG) , compact (EG, MG) , high-moment (CG, WE) , silent-operation (QH, QE, QW, QR) , and integrated measurement (positioning linear guides) . This extensive portfolio enables seamless adaptation to diverse industrial demands.

What further distinguishes HIWIN is its emphasis on interchangeability across multiple series, which streamlines customer logistics and supports flexible machine design and maintenance. Beyond universal load ratings, HIWIN provides specialized solutions, such as the CG Series for applications requiring moment rigidity and the WE/QW Series for wide-rail stability and torsional resistance, underscoring HIWIN’s deep understanding of complex market demands.